Editor's note: When I first cruised the ICW, I had mostly day sailed and the engine did not get much of a workout. Cruising on the ICW involves long hours of engine running, often at relatively low RPMs which is not the best strategy for long-term engine durability. I asked Max Parker, Vice President of Yard Operations for Zimmerman Marine, if he would give us his insight from 25 years of experience servicing ICW cruisers on how to best maintain our engines for trouble-free operation.

Before setting off on a trip up or down the ICW, there is considerable attention you should pay to your engine(s). This may be the first time the boat has ever run for hours on end, day after day, and any weaknesses are bound to come to the surface. While an engine brand-specific mechanic can perform the equivalent of a pre-purchase inspection that will provide a thorough evaluation of the present condition along with recommendations for upcoming maintenance, there are quite a few things that the owner can check in advance. Whether you chose to have a professional do the work or not, there may be times when no one is immediately at hand, and of course, an ounce of prevention is worth a pound of cure.

Quiet Time in the Engine Room

Let's head down to the engine. With everything off, the engine cool, and no other distractions, open a copy of your engine manual. Look at the recommended service tables. All manuals state recommended engine hour times or calendar times for things like fluid changes, valve adjustments, and heat exchanger inspections. There are occasions where an engine might have been run very little over a period of years when replacement is still necessary for items like raw water impellers, hoses, belts, or motor mounts. Rubber degrades over time and has a measurable lifespan delineated in your manual.

If you don't have prior service histories, it is better to assume nothing and start anew. The manual will also state the expected wide-open throttle (WOT) rpm that you will need when you perform a test run before your trip. More about that in a minute.

- Carefully and objectively look at the engine and the drip pan beneath it. Are there fluids in the pan? Where did they come from?

- Is the engine rusty from water leaks, covered in oil from leaking seals, or is there excessive belt dust from a misaligned or worn-out V-belt?

- Inspect the raw water pump. Most have an opening on the side that will show if an oil or seawater seal is leaking.

- Inspect the heat exchanger for leaks.

- Check in the manual to see if there is an anode that should be changed.

- Use your cell phone camera to reach places where your head won't fit.

- Inspect the engine mounts for cracked rubber or loose or rusty hardware. -** Look at the fuel filter bowls** which should have nothing but clean fuel in them. A useful feature is to have a fuel vacuum gauge installed that will indicate when it is time to replace the filter and can help diagnose other fuel-related problems in the future. The gauge pictured will fit Racor 500, 900, and 1000 series fuel filters.

Leaks can travel some distance before they hit the pan or a stringer, but gravity can't be denied. Follow the drips up and try to identify the highest point at which the leak may have begun.

Turbos, intercoolers, or aftercoolers have service intervals and the hard running for which you are preparing can exacerbate the symptoms a partially clogged or worn unit will cause possibly producing costly and time-wasting repairs.

Check out the ends of hoses. If the hose is beginning to fail, often the end will look like it is delaminating. Look for any bulges or areas that might be chafing that also might indicate an imminent failure.

Wipe down the engine with rags and grease remover. Clean the drip pan and place fresh oil absorbent pads in it. Note that different color engine parts probably indicate a part that has been replaced. By the same token, if service was supposed to be performed on a part of the engine and the paint is original and unbroken at the gaskets or fasteners for that part, it may not have been done.

Broken, missing paint and corrosion usually indicate the beginnings of a leak. Hoses may need to be replaced, heat exchanger end cap gaskets replaced, or the exchanger may be leaking. Once the leak is resolved, wire brush the corrosion, clean with denatured alcohol, and touch up with engine paint.

We're just about ready to start the engine, but first, disconnect the shore power cord. There is nothing like starting the engine to perform a good load test on the batteries and a running battery charger may mask a dying bank.

Next, turn the ignition key to the first position and listen for alarms. All of the warning lights and sounds should work confirming that they should alert you if loss of oil pressure, overheating, or low voltage should occur.

The humble engine panel displays a wealth of diagnostic information about your engine. Know your normal ranges when you are running and keep an eye out for changes. Log your maintenance against the hour meter.

Fire Her Up

Now, let's start the engine. We'll want to look for answers to a few questions.

-

How quickly does it start? A slow-turning engine may indicate a dying battery bank, starter, or starter wiring.

-

How much does it smoke and what is the color of the smoke? A mechanic can draw many conclusions from looking at the exhaust of an engine.

-

White smoke may be no more than steam, but it could also indicate malfunctioning glow plugs if there is too much of it.

-

Bluish grey smoke might indicate incomplete fuel burning. This might also be accompanied by a fuel sheen on the water.

-

Black smoke may indicate oil being burnt. This could be from worn piston rings or a leak in the head gasket.

-

Is there good water flow? Seawater cooled engines use water to cool themselves unless the boat has dry exhaust. The water passes through the engine and out the exhaust. There should be a healthy amount at idle and we'll check it again underway. Your engine manual will list the spec water flow at various RPMs, take a bucket and check yours. If it's less, some part in the water cooling circuit is passing less water than the engine needs, check each one in turn.

-

How much does the engine shake at idle? If the engine dances around on its mounts, the mounts may be shot or the idle may be set too low. The manual will confirm the proper rpm. High output alternators can also bog an engine at idle if not regulated properly. These questions are going to be relative to your engine, but it is a good idea to pay attention and form a baseline.

A Critical Test Run

Checking the engine performance underway without distractions and with a critical eye can provide valuable insight into how it runs. Problems that might be overlooked during a quick motor away from the marina to your favorite anchorage or cocktail cruise might not hold up to weeks of use on the ICW. Bring help with you so you can spend time watching the engine without worrying about navigating. Note that the bottom and running gear should be clean and free of any marine growth. The engine should be warmed up by the time your pre-checks are complete. Check the engine gauges to verify that they all work.

- The temperature gauge should have started registering a temperature but won't be up to its maximum which should be somewhere around 180-196 degrees F for most engines.

- The oil pressure should be somewhere around 20 psi at idle and 60 psi underway. (This can fluctuate 10 or 15 psi depending on the engine and temperature.)

- The voltmeter should read above 12.8 volts but not over 14.4 volts for a 12-volt boat and double that for a 24-volt boat. Note the tachometer reading at idle should usually be between 800 and 1000 rpm. A mechanic will typically double-check the tach readings with a hand-held strobe tach to be sure the tach is reading properly.

Make a table of the various checks and record the data.

Once you have clear space to run the boat, bring the boat up to 2000 rpm. Write down the gauge readings, then check on the engine.

- Watch for excessive vibration.

- Look for oil, fuel, coolant, or exhaust leaks.

- If you have an infrared pyrometer (touchless thermometer) and having one is highly recommended, check the temperatures of every hose. Follow the water path from the strainer up to the water pump, into the heat exchanger, through the thermostat and engine, and out the exhaust elbow. Temperatures should be below 190-degrees F except for the section of exhaust piping at the back of the engine before the water gets injected into the exhaust elbow to cool it. This area is often lagged or blanketed to help prevent burns because it is not unusual to see temperatures well over 200-degrees F. The Fluke 62 MAX Mini Infrared Thermometer is a good choice.

- Ask your helmsperson to increase throttle a few hundred rpm and repeat the process, writing down the results in your table.

- Don't forget to check the exhaust for excessive engine smoke and water flow.

- Repeat this until you reach the wide-open throttle. Keep an eye on the temperature gauge as rpm increases.

"Giving Her the Beans"

All engines should be able to run at wide-open throttle (WOT) for a period of time - usually something like one hour out of every eight. For a sea trial, we won't need to run for that long. Ten to 15 minutes is usually enough to know if something is wrong. Since we are trying to find deficiencies during our sea trial, don't be afraid to perform this test. There may be a time when it is necessary to run wide open to save the boat or a crew person and it is better to find out now. Additionally, WOT throttle provides a stress test to reveal weaknesses, such as a marginal cooling system.

The first thing to check should be whether the engine turns up to full-rated rpm. Either the engine manual or the nameplate on the engine will give you this figure. This is a check for proper prop pitch and shaft alignment. Note that either could have been set correctly originally, but wear or an impact could have changed one or the other or there could be other issues.

- Feel for excessive vibration or odd rattles both in the hull and the engine itself.

- Write down the max speed and check with a reciprocal course to eliminate current or wind influences.

- Watch the temperature gauge to be sure the engine does not overheat. If it does, don't shut off the engine. Quickly bring it down to idle. This will let the water pumps continue to circulate coolant and seawater unless the overheating happened because the engine stopped pumping water for some reason like a clog or failed impeller. Still, it is better to circulate coolant to help cool the engine at idle.

A WOT test can also illuminate a problem with a turbo, a fuel restriction (excessive vacuum or faulty fuel pump or injectors), or an intake air restriction (fouled air cleaner or intercooler).

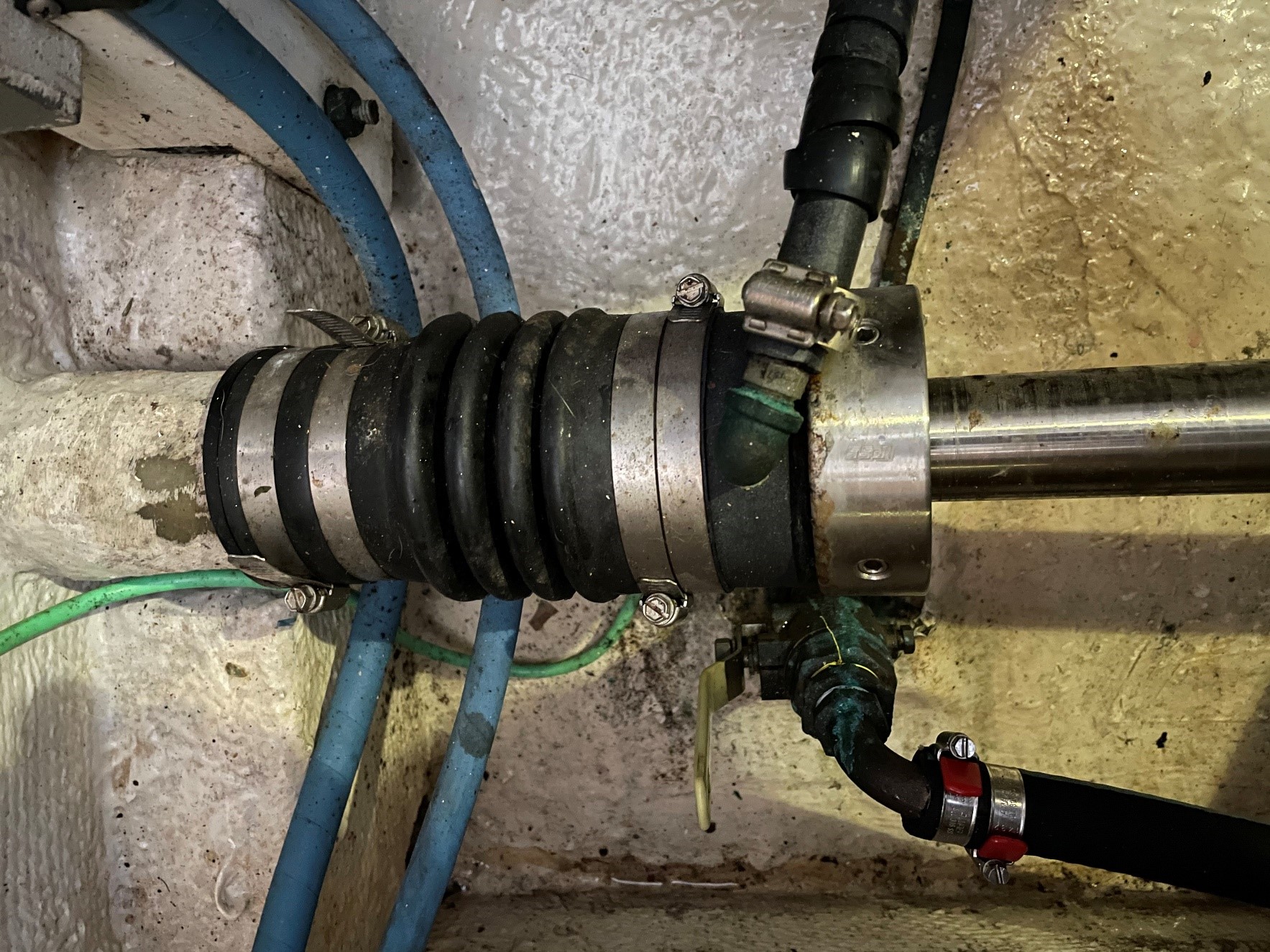

A dripless shaft seal should not leak.

A conventional stuffing box needs to leak approximately a drip every 20 seconds to lubricate the flax packing and shaft. Check the shaft for vibration under WOT and either type of seal for excessive heat (over 120-degrees F) with a touchless thermometer. Water injection hoses should be removed with the engine running to confirm good water flow.

After the WOT test, slow the boat back to cruising speed and return to the dock. Once the boat is secured, go back into the engine room and check the engine and the pan under the engine for fluids, noting any leaks and possible sources.

After the engine has cooled a bit, it is a good idea to take or have fluid samples taken for lab analysis. We regularly check engine oil, transmission fluid, and coolant and have proven that sampling can catch problems before they cause a crisis. Fluid samples can highlight higher levels of wear metals, water or coolant in the oil, and any number of other potential issues.

What happens after the sea trial depends on your mechanical abilities. In some cases, the testing may illuminate issues that need to be resolved by trained professionals. Zimmerman Marine has seven boat yard locations along the East Coast convenient to the ICW. Having the data from your sea trial can be a real plus for speeding up a diagnosis and repair.

Let's Go Already

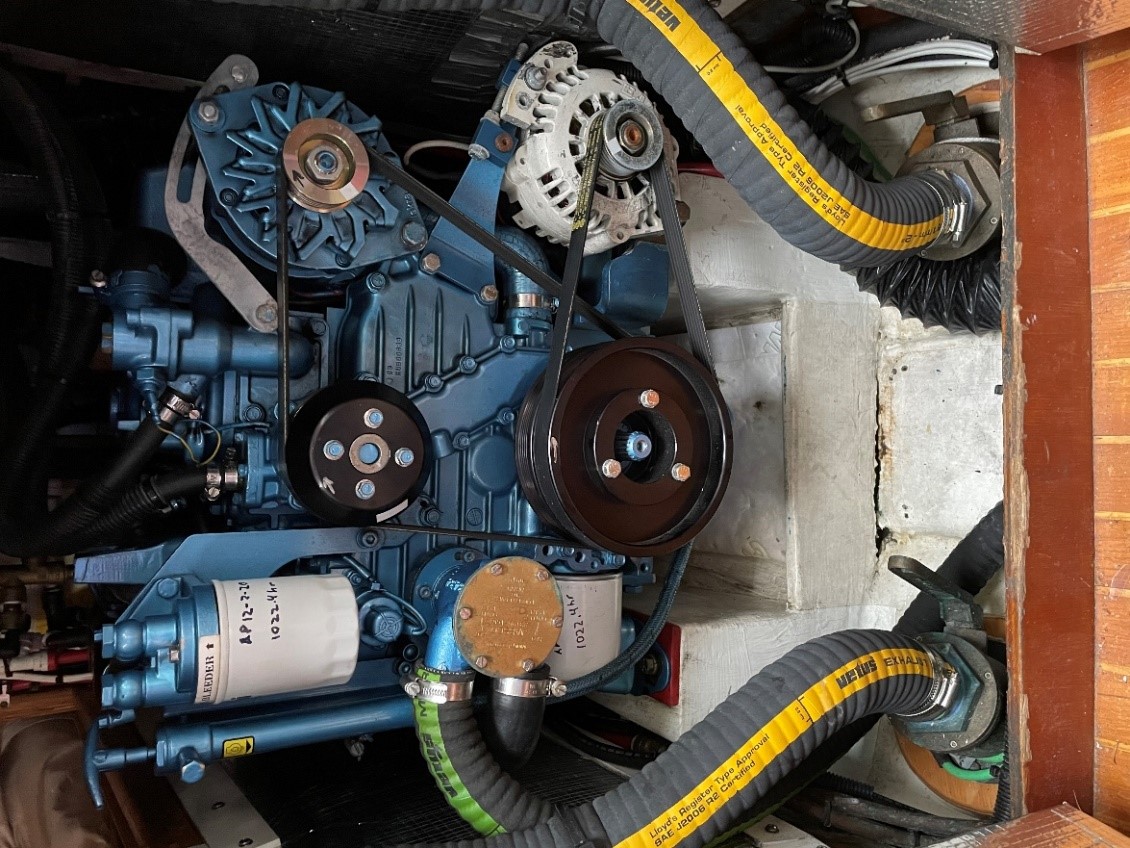

Now you're ready to leave. The engine(s) is freshly painted, belts are new, the impeller has been replaced, there is fresh oil and a new filter, and the fuel filters are spotless. What can you expect from your engine underway? Good skippers will make a checklist and work through it before starting the engine each morning. Think of it as an aircraft pre-flight check. At a minimum,

- Check the oil and coolant levels,

- Check that the fuel filters are still clean

- Check for leaks.

- Monitor the shaft stuffing box for any changes

Leak checks during the day and engine gauge monitoring are also good ideas. It is amazing how many things can be caught before they become a crisis just by regular inspection.

This engine is squared away. The pan is clean, the filters are labeled, and the belts are new and properly tensioned.

What speed or rpm to run the boat is going to depend greatly on your boat and engine configuration. The ICW has many sections labeled no wake and we always encourage skippers to be aware of what their wake is doing to fellow travelers and those on shore.

Most of the time, sailboats and displacement power boats will want to run just under their displacement speed which can be calculated by finding the square root of their waterline length times 1.3. Most properly propped boats with enough horsepower will find the best fuel efficiency at this speed. Miles per gallon will drop dramatically above those speeds but making a lift bridge schedule or marina reservation may make it worth the fuel to run a little faster.

Given the space to run, it's a good idea to periodically run the engine up to full throttle for a few minutes. This helps reduce carbon buildup and oil sludge from too much low rpm running typical of ICW transits. Planing boats may have long periods when they wonder if they will ever get to go fast again and will also benefit from periodic WOT.

If you do have issues underway, hopefully, better familiarity with your engine may help for a quick resolution. If not, Zimmerman Marine has boatyards from Maryland to South Carolina with skilled mechanics and electricians ready to help. We use a shared database so if you visit any of our yards, any of the other yards can see the work orders and any other common information. We routinely send parts ahead to the next yard you might visit and can make adjustments to work done or perform warranties from one yard to the next. We are fortunate to stay busy so planning for major work is always helpful, but we do try to set aside some time to keep cruisers with failures going.

Have a great ICW cruise, Max Parker Vice President of Yard Operations Zimmerman Marine

This article was written and published in the ICW Cruising Guide by Bob423 which can be found and purchased inside of the Waterway Guide Mobile App.