A marine toilet is a relatively simple apparatus, straightforward to diagnose and repair. There are a handful of major manufacturers; most have replacement parts and maintenance items available for purchase via marine chandleries.

Repair is generally a matter of understanding the system and getting your hands dirty.

Marine toilets come in two major types: Manual and electric – but both systems work essentially the same way. In the case of an electric system, water is drawn into the toilet and pushed out at the press of a button, and an electric pump does all the work. In a manual system, the user operates a plunger mechanism, drawing water into the toilet, and pumping waste out.

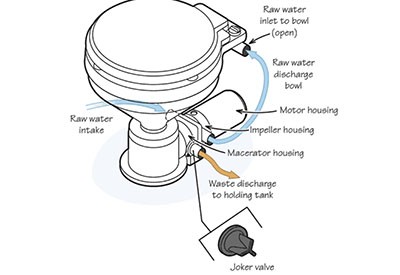

Here's how it works. Water is drawn into the toilet by pumping the plunger. The plunger creates a vacuum that draws seawater into the toilet via a through-hull and seacock arrangement and a ¼" hose. The toilet bowl fills with seawater, allowing it to flush the waste. Next, the user will use the same plunger to create pressure, pumping the waste from the bowl into the waste holding tank via a larger 1 ½" hose. With use, the holding tank will fill, and will require a 'pump-out' (connecting a shore-based pump to the waste deck-fitting and suctioning the contents into a shore-based tank).

Important Parts Make Up the System

A 'vented loop' is added in two places – between the through-hull and the toilet, and between the toilet and the holding tank. Because the toilet, the plumbing, the through-hull and the holding tank are all mounted below the vessel's water line, the water lines need to be broken up with vents that are mounted above the waterline – this prevents water and waste from flowing freely from the tank, to toilet and through-hull (and vice-versa.)

Mounting vented loops appropriately and ensuring that the vents are free of debris is one of the most critical parts of a functioning waste system. As you can imagine, water free flowing from a through-hull into the toilet can fill the bowl – and if left unattended can overflow, filling the boat!

A 'joker valve' is a one-way valve that allows waste to be pumped out of the toilet bowl, but won't allow it to flow back in. These rubber devices stretch and wear out over time and are one of the more common items to be replaced in a waste system.

Many boats have a macerator pump located between the toilet and the holding tank. This pump acts to break up any solids to allow waste to flow appropriately.

The following are a list of common problems and solutions:

- Lack of suction to pump water into the bowl and/or waste out of the bowl. Ensure that all hose clamps are tight, hoses are intact and that the plunger o-rings are making good contact with the plunger housing. Remove the plunger and replace the o-rings as necessary.

- Odors. The smell is caused by waste sitting in low spots of the hoses and venting from the holding tank into the cabin spaces. Ensure that the hoses are run to eliminate low spots and consider installing an odor filter in the hose line between the toilet and holding tank. Ensure that the hoses used are non-permeable and are rated as sanitation hose

- Clogging. Relatively small hoses and low water volume and pressure are used in marine toilets, especially when compared with household toilets. Use marine-rated, biodegradable toilet paper – and use it sparingly. If a clog is evident, work to determine where the clog is located, and disassemble/remove, rather than using drain cleaners.

- Waste flowing back into the toilet. This is often a symptom of a poorly placed (or clogged) vented loop, or a worn joker valve. Check both and repair/replace as necessary.

Winterizing a marine toilet, in a few simple steps:

- Close the through-hull seacock and remove the inlet hose. Pump the system dry.

- Pump-out the waste holding tank (to a shore facility)

- Pour antifreeze into the inlet hose and pump into the bowl. Pump the toilet dry and into the holding tank. This will allow antifreeze to flow through the entire system, displacing any water.

Nothing can ruin a vacation, or even an evening aboard like a broken, malfunctioning or unusable toilet – hope this helps to keep yours running well!

Andrew McDonald is the owner of Lakeside Marine Services – a boat repair/maintenance firm based in Toronto. Andrew has worked in the marine industry for 12 years and is a graduate of the Georgian College 'Mechanical Techniques - Marine Engine Mechanic' program.