For rope used in ground tackle, whether as a rode, pendant, snubber or bridle, it is important for it to have enough stretch in order to cushion surge loads, those loads that are the result of wind gusts and seas. But it isn’t simply “stretch” that is important, it’s “reserve stretch” that counts.

Once the wind pulls its share of stretch out of rope, it’s the stretch that remains in the rope that is used to cushion the wind gusts and seas. If there is not enough “reserve stretch”, the rope will become taut reducing its ability to cushion surge loads.

To have enough “reserve stretch” a rope needs three things:

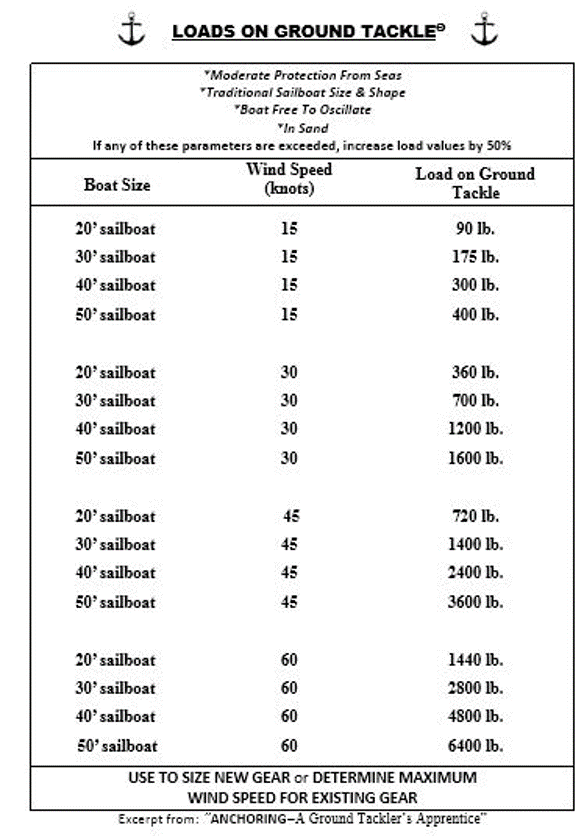

- Tensile strength that is at least eight times the highest load- Using the data from a load table (see insert), multiply the highest anticipated load by eight. Then, go to the rope manufacturer’s literature and match this figure to a corresponding rope size.

- Stretch that is at least seven percent at fifteen percent load. This limits the choice of rope to nylon, either three-strand, eight-plait, or twelve-braid construction.

- Long length- As the wind approaches gale-force levels, a pendant, snubber or bridle, or the rope portion of a combination rode should be a minimum of thirty feet in length; for storm force winds at least forty feet.

With all three of these criteria met, rope, whether as a rode, pendant, snubber or bridle will have plenty of stretch for heavy conditions, and paradoxically, still be able to provide stretch in light conditions.

As an added benefit, the rope will be harder to cut, more chafe resistance, as well as its fibers, being more resistant to melting.

Should a rode be made of a low-stretch material, such as a chain or polyester rope, installing a nylon snubber or bridle, sized as noted above will provide the needed stretch. But a snubber or bridle is also a good idea for rope rodes, too, as: 1) a snubber or bridle removes the load from the windlass’ mechanism; and, 2) if chafe develops, let it be a snubber or bridle that chafes, leaving the rode healthy in order to “catch” the boat should the snubber or bridle part.

Regardless of how chafe, cut or melt resistant a rope is, adequate anti-chafe techniques still need to be utilized.

As a final point, rope can be manufactured to two standards: 1) Cordage Institute standards, which designates specific diameters and tensile strengths; it is to this standard that rope-chain gypsies are sized; and, 2) Non-Cordage Institute standards, in which the diameter may differ, often bigger from that designated by the Cordage Institute standards, though its tensile strength must match that published by the manufacturer. A list of Cordage Institute members can be found at www.ropecord.com.

BIO

Speakers, cruisers, live-aboards, and authors of the book, ANCHORING-A Ground Tackler’s Apprentice, available at: https://www.waterwayguide.com/ship-store. Visit their website: trawlertrainingabc.com or contact, rudysechez@gmail.com.